The Best Inventory Management in Trades Without ERP: Ultimate Guide 2025

Introduction to Inventory Management in Trades

The Importance of Efficient Inventory Processes in Daily Operations

The best inventory management in trades without ERP is far more than just an administrative tool for small and medium-sized businesses. It is the difference between profitable and loss-making projects. Every day, trade businesses lose valuable time and money through inefficient inventory processes. An electrician who discovers on the construction site that important cables are missing. A plumbing business that orders expensive fixtures twice because no one knew they were already in stock. A carpentry shop that cannot accept a lucrative project immediately because it's unclear whether enough wood is available.

These scenarios repeat daily in German trade businesses. The cause is rarely a lack of willingness to organize, but rather missing practical tools that fit the reality of trades. While large industrial companies work with complex ERP systems, trade businesses need solutions that work quickly without requiring an IT expert in-house.

Well-functioning inventory processes mean concretely: Technicians know immediately on the construction site which materials are available. Reorders happen automatically before materials run out. Tools are no longer bought twice because no one knows where they are. Projects can be planned reliably because material inventory is transparent. These advantages sound self-evident, but in practice, they are still wishful thinking for many businesses.

Why Many Trade Businesses Don't Use ERP

The decision against an ERP system is usually a conscious and understandable choice for trade businesses. ERP systems were originally developed for large manufacturing companies and bring complexity that simply isn't needed in trades. A plumbing business with ten employees doesn't need production planning across multiple plants, no complex cost center accounting, and no multi-stage approval processes.

Investment costs for ERP systems often start at several thousand euros for licenses and weeks of training. Many master craftsmen report failed ERP projects where, after months of implementation, the system was so complicated that employees switched back to Excel lists. Implementation ties up valuable working time that is missing in day-to-day operations.

Particularly critical is the fact that classic ERP systems were not designed for mobile use. But tradespeople work largely outside the workshop, on construction sites, in stock rooms, or on the road between customer appointments. A system that only works on the office PC simply doesn't fit the reality of modern trade work. The best inventory management in trades without ERP, on the other hand, must work exactly where the work happens: mobile, fast, and uncomplicated.

Challenges in Inventory Management Without ERP Systems

Error-Prone Paper-Based Processes

The classic paper-based process is still surprisingly widespread in German trade businesses. At first glance, it seems practical: A technician takes material from stock and notes it on a piece of paper. At the end of the week, these notes should be transferred to the system. In reality, however, something else happens. Notes get lost, become illegible, or end up crumpled in a pocket and accidentally go through the washing machine. The result: No one knows exactly which material was actually consumed.

These seemingly small information losses add up to significant economic damage. Material is consumed but not invoiced to the customer because proof is missing. Inventory in accounting doesn't match reality, leading to nasty surprises during inventories. It becomes particularly problematic when multiple employees have simultaneous access to stock, but each maintains their own system of note papers.

A painting business from Cologne reported a typical case: Over several months, high-quality paints worth several thousand euros were regularly missing during inventory. Suspicion initially fell on theft. The resolution was more mundane: Employees had taken material for projects but noted it on papers that never made it to accounting. The material was consumed and charged to the customer but never deducted from inventory. The difference between target and actual grew larger over months.

Lack of Transparency in Inventory

Without digital inventory management, many businesses have permanent uncertainty about actual inventory levels. The question "Do we still have enough material for next week's project?" can often only be answered by checking stock. This not only costs time but leads to reactive rather than proactive work. Instead of planning projects securely, businesses work in "let's see what's still there" mode.

It becomes particularly critical for businesses with multiple inventory locations. An electrical business might have a main stock room in the workshop, material depots in company vehicles, and possibly an external storage location for large projects. Without a central digital overview, no one knows where which material is located. The consequence: Expensive material is reordered even though it's three streets away in the van.

The lack of transparency affects not only management but especially employees who work with it daily. Technicians spend valuable time on phone calls to the workshop to clarify whether material is available. Dispatchers cannot plan projects reliably because they don't have an overview of the material situation. These information gaps lead to frustration in the team and missed business opportunities when orders must be declined even though sufficient material would be available.

Time Loss Through Manual Processes

The biggest hidden cost factor in manual inventory management is time. Every manual inventory recording, every Excel list that must be maintained, every reorder that is triggered manually costs valuable minutes. These minutes add up to hours, the hours to days. A realistic calculation for a medium-sized trade business looks like this: If three employees each spend twenty minutes daily on inventory organization, that's five hours per week, about twenty hours per month, and 240 hours per year of pure organizational effort.

At an average hourly rate of fifty euros for skilled workers in trades, this corresponds to an annual loss of 12,000 euros! Money that could have been earned with productive work. Added to this are the costs of errors: Incorrectly recorded inventory leads to wrong orders, urgent reorders to higher procurement costs, missing parts to project delays and dissatisfied customers.

Manual inventory management has another disadvantage: It only works as well as the discipline of those who maintain it. In stressful phases, when there's especially much to do, inventory maintenance becomes a bothersome side task that gets postponed. But exactly then, when many projects run in parallel, precise inventory knowledge would be most important. The best inventory management in trades without ERP breaks this vicious cycle by making processes so simple that they work even under stress.

The Best Inventory Management in Trades Without ERP – What Does That Mean?

Criteria for an Optimal Solution

The best inventory management in trades without ERP is characterized by one fundamental property: It adapts to the way trades work, not the other way around. While ERP systems demand that businesses adapt their processes to the software, a good inventory solution should digitize and improve existing practice without turning everything upside down.

The first criterion is speed. In trades, every minute counts. An inventory solution must be so fast that recording a withdrawn material takes less time than writing a note. If the system is slower than the previous method, it won't be accepted, no matter how many features it offers. The reality on the construction site doesn't allow cumbersome input forms with twenty required fields.

The second criterion is reliability. Trade businesses need systems that work even when the workshop manager is on vacation for two weeks or when a new apprentice starts. The software must be so robust that even under difficult conditions like poor internet connection, dusty environment, hectic on the construction site, the basic functions remain available. A system that fails at the smallest disruption is useless in trades.

The third criterion is cost-effectiveness. The total costs of an inventory solution must be in a reasonable ratio to the benefit. This isn't just about license costs, but the total calculation: acquisition, training, ongoing costs, and time spent on maintenance. The best inventory management in trades (without ERP) pays for itself within a few months through saved time, reduced material losses, and better project planning.

Practicality, Mobility, Automation

Practicality means concretely that an electrician who just took a NYM 3x1.5 mm cable from stock for the construction site can document this with just three taps on their smartphone. No login to a separate system, no complicated menu structures, no forms with dozens of fields. The software ideally recognizes who is taking material and to which construction site it must be assigned.

Mobility in trades is not a nice additional feature but an absolute basic requirement. Work happens everywhere – just not at the desk. Technicians work at the customer's, technicians on changing construction sites, material is brought directly from the supplier to the construction site. An inventory solution that only works on the PC in the workshop ignores the reality of modern trade work. Every employee must have access to current inventory information on their smartphone and be able to record movements.

Automation is finally the key to time savings. The best inventory management in trades independently recognizes when inventory is running low and triggers ordering processes before material runs out. It learns from past projects which materials are typically needed together and makes intelligent suggestions. It recognizes patterns in consumption and warns in time when unusually high material consumption occurs. This automation frees tradespeople from constantly checking stock and from the mental burden of always having to think about reorders. Autonomous software can even completely free from manual reorders.

Important Features of Modern Inventory Management Without ERP

Mobile App Usage

The mobile app is the heart of every modern inventory management in trades. It transforms every employee's smartphone into a mobile inventory terminal. A plumbing installer who is currently loading their van with material opens the app, scans the barcode of the material used, and confirms the withdrawal with a tap. The information is immediately in the system, inventory is updated, and if the material falls below minimum stock, a reorder is automatically triggered.

The real strength of mobile inventory management shows in everyday situations that previously led to problems. A project manager stands at the customer's and is asked if an additional order next week would be possible. Previously, they would have had to say: "I need to check in the workshop first if we have the material." Today they open the app, see availability within seconds, and can commit directly. This not only makes a professional impression but also secures spontaneous orders that would otherwise be lost.

Modern mobile inventory solutions also offer offline functionality. On construction sites in basements or rural areas without mobile reception, material withdrawals can be recorded. As soon as an internet connection is available again, the app synchronizes automatically. This robustness is crucial because tradespeople can't wait until they're in an area with good reception again. Work must continue, and inventory management must keep up.

Barcode Scanning

Barcode scanning eliminates the biggest weakness of manual recording: human errors in input. An electrician who has twenty different cable types in stock no longer needs to think about whether the correct article name is "NYM-J 3x1.5" or "NYM 3x1.5mm²". They simply scan the code, and the system knows exactly which material it is. This not only reduces errors but also speeds up the process enormously.

The technology is so mature today that scanning works with any standard smartphone. Dedicated barcode scanners are not strictly necessary, even if they're more practical in some environments. The smartphone camera is completely sufficient to reliably capture codes. Many materials already come from the manufacturer with barcodes, so no additional labeling is needed. For own products or loose materials, simple label printers can be used that cost less than an average cordless drill.

Barcode systems also enable precise traceability. When a customer complains months later that an installed part is defective, it can be exactly traced when which batch of which material was used. This protects against unjustified complaints and helps in justified warranty cases to quickly find the origin of the problem. In industries with strict documentation requirements like electrical engineering or in the medical field, this traceability is not only practical but legally required.

User-Friendly Inventory Management

User-friendliness decides whether a system is used in daily operations or disappears in a drawer. The best inventory management is so intuitively designed that a new employee can work productively with it after a five-minute introduction. Complicated menu structures, cryptic technical terms, or nested settings have no place in a tradesperson's inventory solution.

Good inventory management shows the most important information at a glance. Which materials are critically low? Which articles are used most frequently? Where are the largest inventories currently located? These questions must be answerable within seconds, not after browsing through several submenus. Visual elements like traffic light colors help: Green for sufficient inventory, yellow for materials that should soon be reordered, red for acute shortages.

Inventory management must also be able to represent different inventory locations. An electrical business might have a main stock room, three service vans, and a parts storage for larger projects. The software must transparently show where which material is located and enable transfers between inventory locations with minimal effort. When a technician brings material from their vehicle back to the main stock room, that should be a matter of ten seconds, not ten minutes.

Automatic Alerts & Minimum Stock Levels

Automatic alerts are the key to ensuring trade businesses never again stand in the middle of a project without material. The system continuously monitors all inventory and compares it with defined minimum quantities. As soon as a critical value is undershot, responsible persons receive a notification – via app, email, or SMS, depending on urgency.

The intelligence lies in the intelligent setting of minimum stock levels. These should not be static but oriented to actual consumption patterns. A material used every day needs higher minimum stock levels than specialty parts only needed for specific projects. Modern systems analyze historical consumption and automatically suggest sensible minimum stock levels. A painting business that regularly needs facade paint in spring and summer but hardly in winter should have season-dependent minimum stock levels.

This function becomes particularly valuable in combination with automated ordering processes. When a minimum stock level is undershot, the system can not only warn but directly trigger an order with the preferred supplier. Typical order quantities are considered so that unnecessarily small or large quantities aren't ordered. A plumbing business that normally always orders ten pieces of a certain valve will also receive this quantity in automatic ordering, even if technically three pieces would suffice. This optimizes procurement costs and utilizes volume discounts.

Advantages of Specialized Inventory Solutions Over ERP Systems

Low Costs

The cost difference between specialized inventory solutions and ERP systems is dramatic. While ERP implementations quickly reach five-figure amounts, modern inventory management apps start at monthly costs of fifty euros. Even if barcode scanners and possibly additional smartphones for employees are included, the total investment is in the low four-figure range. Costs that typically pay for themselves within three to six months.

The low costs arise from the lean feature profile. While ERP systems try to map all business processes, specialized inventory solutions focus exclusively on what's really needed: inventory management, material withdrawals, reorders, and inventory. No overloaded modules for personnel planning, financial accounting, or production control that no one uses anyway. This focus makes the software not only cheaper but also better at what it does.

Also important is the aspect of hidden costs. With ERP systems, high consulting costs, individual adaptations, and expensive training often come on top of license fees. Specialized inventory solutions, on the other hand, are designed so they can be implemented without external consultants. Most providers offer video tutorials, online support, and sometimes even free initial consultation. A trade business can thus introduce the solution internally without causing external costs.

Quick Implementation

While ERP implementations take weeks or months, specialized inventory solutions are often operational within a day. The process is typically simple: Download software or open in browser, enter master data of the most important materials, define minimum stock levels, create employees, and get started. Many systems offer import functions for Excel lists, so existing article lists don't need to be laboriously re-entered.

Quick implementation has a psychological advantage: The team sees results immediately. Instead of investing weeks in an abstract system that might work someday, employees experience concrete improvements already on the first day. A technician scans their first material, inventory is updated, and at the next look into the system, everyone sees the current situation. This quick success motivates further use and overcomes natural skepticism toward new systems.

Quick implementation also means businesses stay flexible. If it turns out that a solution doesn't fit after all, only a few days have been invested, not several months. This low entry barrier makes it easier to take the step toward digitization at all. Many businesses have avoided software projects in the past because they had bad experiences with lengthy implementations. Specialized inventory solutions break through this threshold.

No Training Barriers

A central advantage of lean tools is minimal training necessity. The systems are designed to be self-explanatory. A smartphone can be operated by practically anyone today, and modern inventory solutions use exactly this familiarity. The gestures and operation concepts correspond to what people know from other apps: Swiping, tapping, scanning. There are no proprietary user interfaces that must be laboriously learned.

This is particularly important for businesses with employees of different generations. While younger employees grew up with apps, experienced master craftsmen sometimes have reservations about technology. An intuitive inventory solution bridges this gap. When a sixty-year-old workshop manager sees that they can simply scan a code with their smartphone instead of laboriously maintaining an Excel list on the PC, the benefit is immediately recognizable. Acceptance increases dramatically when the new system is simpler than the old method.

Training is usually limited to a short introduction of thirty minutes in which the basic functions are shown. Record material withdrawal, check inventory, trigger reorders – these are the core functions everyone must master. Advanced functions like inventories or reports can then be learned by individual persons as needed. This graduated complexity prevents employees from being overwhelmed by too many functions.

Flexibility for Small Businesses

Small trade businesses have special requirements for flexibility. Business models change, specializations are adjusted, the team grows or shrinks. Software must be able to keep up with this dynamic without expensive adaptations being necessary each time. Specialized inventory solutions are typically modular: A business starts with basic functions and can book additional modules as needed.

A painting business that initially only wants to digitize its paint inventory can do exactly that. If the decision is later made to also record tools and machines, that can be easily expanded. When the business grows from three employees to ten, the software simply scales with it. This flexibility is rarely given with ERP systems, where licenses are often tied to user numbers and expansions trigger complex adaptation projects.

Flexibility is particularly valuable for seasonal fluctuations. A landscaping business might have only two employees in winter but ten seasonal workers in summer. With a flexible inventory solution, users can be activated and deactivated as needed without the entire license structure having to be adjusted. This adaptability saves the budget and avoids unnecessary complexity.

Step-by-Step: How Businesses Choose the Best Inventory Management in Trades Without ERP

Needs Analysis

The first step to a successful inventory solution is an honest needs analysis. Trade businesses should ask themselves concrete questions: Which materials are used most frequently? How many different inventory locations are there? How mobile do employees work? How urgent is the problem of missing materials? From these answers, a clear requirement profile emerges.

A practical method is to note all situations over two weeks where current inventory management leads to problems. When was material searched for in vain? How often did an urgent reorder have to be made? How much time was spent on inventories or stock checks? This documentation not only shows the weaknesses but also provides metrics later by which the success of the new solution can be measured.

Also important is involving all stakeholders. The workshop manager has different requirements than the technician on the construction site, and accounting needs different information again. A needs analysis should consider all these perspectives. Only when the solution offers real added value for all user groups will it be accepted and used.

It can also be useful to ask your suppliers for a list of the most ordered materials (top sellers) within the last 12 or 24 months. Start your digitization with these top sellers to generate maximum benefit.

Feature Comparison

After the need is clear, follows the systematic comparison of available solutions. Trade businesses should not make the mistake of being dazzled by extensive feature lists. What matters is not how many features a software theoretically has, but whether it fulfills the really needed functions well. An app with twenty functions, of which fifteen are never used, is worse than a solution that perfectly masters five essential functions.

Critical functions that practically every trade business needs are: mobile recording of material withdrawals, real-time inventory overview, automatic warning or automatic reorder at minimum stock levels, simple inventory function, and export for accounting. Functions beyond that are nice-to-have but not a must. A transparent display of which materials are in which vehicle is valuable for purely mobile trades without stock rooms. Barcode scanning significantly speeds up work.

When comparing, the provider's business model should also be considered. Is it an established solution with long-term perspective or a startup that might not exist in a year? Are there regular updates and further development? How is support organized? A German provider with German-speaking support who understands the peculiarities of trades is often more valuable than an international standard solution.

Test Phase & Employee Feedback

The test phase is the most important step in the selection process. Theoretical evaluations can never replace practice. Serious providers of inventory solutions offer free test phases of at least two weeks, often even a month. This time should be used intensively. Ideally, in the test phase, not just a few sample articles are created, but a realistic section of the actual inventory is digitally mapped.

The test phase should cover all relevant scenarios. A technician should use the app on a real construction site and record material. The inventory manager should conduct an inventory. Accounting should test the export function. Only if the system works in the rough reality of daily trade operations is it a viable solution. A system that works wonderfully in the quiet office but isn't operable on the dusty construction site with gloves fails.

Employee feedback is crucial. The best technical solution is worthless if the team doesn't accept it. Regular short rounds during the test phase help recognize problems early. Perhaps the app is too slow on older smartphones, or the menu navigation isn't intuitive. Many of these problems can be fixed through configuration or by choosing a different solution. Important is that feedback is taken seriously and flows into the decision.

Comparison: Typical Inventory Solutions Without ERP

Mobile Tools

Mobile apps have established themselves as the best inventory management in trades because they perfectly fit the mobile way of working. These solutions are designed from the ground up for smartphones and tablets. The user interface is optimized for touchscreens, functions are designed for quick access, and the entire architecture considers that users often work offline or with poor connection.

The great advantage of mobile tools lies in their ubiquity. Every employee has their smartphone with them. On the construction site, in the stock room, in the vehicle. No additional device is needed, no special hardware that must be purchased. The threshold to use is minimal. A quick glance at the phone shows if material is available. A quick scan records the withdrawal. This simplicity is the key to success.

Modern mobile inventory solutions like repleno go one step further. They automate not only inventory management but also reordering. When a material falls below minimum stock, an order is automatically triggered with the supplier. The tradesperson no longer needs to remember to order in time. The system takes over this mental burden and ensures that material is always available when needed. This automation frees trade businesses from constant ordering stress and from the dreaded paper-based processes.

Cloud-Based Apps

Cloud-based inventory solutions offer the crucial advantage of central data storage. All information lies on the provider's servers, not on individual devices. This means: Every employee always sees the current status. When a technician in Cologne withdraws material, a colleague in Bonn sees the updated inventory three seconds later. This real-time synchronization is not possible with local solutions.

The cloud architecture also has practical advantages for updates and maintenance. Improvements and new functions are centrally rolled out and immediately available to all users. Software doesn't need to be updated on thirty different devices. The provider takes care of backups, security, and performance. For a trade business, this means: no IT department needed, no own server, no worries about data backup.

Concerns about data security are unfounded with serious providers. Modern cloud solutions use bank-level encryption and meet strict German data protection standards. Data in cloud data centers is often safer than on a local server in the workshop that isn't protected against fire, theft, or water damage. Many providers store data exclusively in German data centers, ensuring GDPR compliance.

Excel/Google Sheets (Pros & Cons)

Excel or Google Sheets as inventory management are a common entry into digital inventory management. The advantages are obvious: no additional costs since the software is usually already available, high flexibility in design, and familiarity of many employees with the tool. For very small businesses with few materials and a single inventory location, a well-maintained Excel spreadsheet can certainly work.

However, disadvantages quickly outweigh as complexity increases. Excel is not designed for mobile use. While there are mobile apps, editing spreadsheets on small smartphone screens is tedious. Supporting multiple users simultaneously is problematic. Version conflicts arise when two employees edit the file in parallel. Error susceptibility is high because every cell must be manually edited.

Particularly critical is the lack of automation. Excel doesn't remind that material must be reordered. It doesn't warn when inventory is critically low. It doesn't trigger orders. All of this must be kept in mind by a person, which exactly creates the mental burden that a good inventory solution should actually eliminate. Excel can be a starting point, but growing businesses quickly hit limits. Switching to a lean solution is then the logical next step.

How Digital Inventory Management Increases Productivity in Trades

Fewer Material Losses

Material losses are an underestimated problem in many trade businesses. They don't arise from theft but from disorder, lack of overview, and insufficient documentation. A typical scenario: An electrician buys a hundred meters of 5mm² cable for a project. They use 75 meters, the remaining twenty-five end up somewhere in stock or in the vehicle. On the next project, a hundred meters are bought again because no one knows that twenty meters are still available. These overstocks tie up capital and clog storage space.

Digital inventory management makes these losses transparent. Every material withdrawal is recorded, every return documented. The system shows exactly which remaining quantities are where. A project manager can check before ordering whether material is available. This not only prevents double purchases but also enables targeted use of remaining stock. Material that lay unused in stock for years suddenly becomes visible again and can be consumed.

Studies on digital inventory systems prove that digital inventory management primarily achieves one thing: fewer material losses, less overstocking, and a significantly more efficient flow between consumption and reordering. Businesses benefit economically from this, as studies on inventory digitization in SME environments confirm.

Better Project Planning

Precise project planning requires reliable information about material availability. With digital inventory management, a project manager can clarify within minutes whether all needed materials for a project are available. No more guesswork, no vague estimates, but hard facts. This security allows committing to projects at fixed dates and optimally planning capacities.

The improvement goes beyond pure availability checking. Intelligent systems can predict based on historical data which materials are needed for typical projects. A plumbing business conducting a standard bathroom renovation automatically gets a material list suggested that's based on previous similar projects. This speeds up planning and reduces the risk of forgetting something.

Better planning also leads to more satisfied customers. Projects that are completed on time because all materials were available leave a professional impression. Customers value reliability. A tradesperson who can say "The project takes three days, and we start next Monday" and keeps this promise stands out from competitors who must postpone dates because material is missing.

Shorter Routes & Smarter Processes

Digital inventory management optimizes not only what is ordered but also how materials are moved in the business. A system that precisely records where which material is located saves countless search minutes. Instead of searching through the entire stock room, the app shows: "Article XY is located in Shelf 3, Compartment 2". The employee goes directly there, takes the material, and can continue working.

For businesses with multiple inventory locations, this advantage becomes even clearer. When material is stored in various vehicles, in the workshop, and on construction sites, transparency is worth its weight in gold. A technician who urgently needs a certain part for a project sees in the app that it's in a colleague's vehicle who is working three kilometers away. Instead of driving to the wholesaler, coordination happens quickly and the part is handed over. This saves driving time, costs, and CO2.

Smarter processes also arise through integration of various processes. When inventory management is connected to project management, materials can be directly assigned to projects. During billing, it's immediately clear which material costs must be invoiced to which customer. This continuous documentation saves time in accounting and ensures that no material costs are lost.

Implementation in Practice

Introduction in Small Steps

Successful introduction of inventory management follows the principle "start small, think big". Trade businesses should not try to digitally capture their entire inventory overnight. A proven approach is to start with the twenty percent of materials needed for eighty percent of projects. These core articles are first taken into the system, labeled with barcodes, and actively used.

After the team has developed routine with these main articles, further materials are gradually added. This step-by-step expansion has several advantages: Overwhelming remains low, quick successes motivate continued work, and the system can grow organically. An electrical business might start with cables and wires, then add switches and sockets, and only later record small materials like screws and dowels.

Important is that clear responsibilities are defined from the start. One person should be responsible for data maintenance, even if many employees use the system. This person takes care that new materials are correctly created, that master data stays current, and that the system is generally maintained. Without this clear responsibility, the system threatens to deteriorate.

Employee Training

Even though modern inventory solutions are very intuitive, minimal training is needed. This should be practical and hands-on. Instead of long theoretical presentations about all possible functions, it's more effective to show the three most important use cases:

- Withdraw and record material

- Check inventory

- Return material

These basic functions cover ninety percent of daily use.

Training should if possible take place directly at the workplace. A technician learns the app best by using it during actual material picking in stock, not in a meeting room in front of a projector. This practical approach builds trust and immediately shows the benefit. When an employee experiences how they save time through a simple scan, they're more willing to use the new system.

Short tutorial videos or cheat sheets showing the most important steps are also helpful. These can be looked up anytime when uncertainty arises. Many providers already provide such materials. A laminated A4 sheet with the five most important functions hanging in the stock room is often more valuable than a hundred-page manual that no one reads.

Control & Optimization

After introduction, it should be regularly checked whether inventory management works as desired. A monthly short meeting where problems, wishes, and improvement ideas are collected keeps the system alive. Perhaps it shows that certain materials are incorrectly categorized or that minimum stock levels must be adjusted. This continuous optimization prevents the system from becoming rigid.

Important metrics should be regularly reviewed: How many materials are below minimum stock? How many reorders were automatically triggered? How often were there material shortages? These numbers show whether the system brings the desired benefit. If it turns out that despite inventory management, material is frequently missing, processes or settings must be adjusted.

Optimization also concerns the physical organization of stock. Digital systems work best when stock itself is well organized. Clear inventory locations, sensible categorization, and clear labeling complement the digital solution. A chaotic stock room will remain chaotic even with the best software. The combination of digital intelligence and physical order is the key to maximum efficiency.

Common Mistakes in Inventory Management Tools – and How to Avoid Them

Unclear Responsibilities

The most common reason inventory management systems fail is unclear responsibilities. When everyone thinks someone else will take care of it, in the end no one does. Material withdrawals aren't recorded, new articles aren't created, minimum stock levels aren't updated. The system deteriorates into an empty shell without real benefit.

The solution is simple but crucial:

- For every process, it must be clear who is responsible.

- Who creates new materials in the system?

- Who regularly checks minimum stock levels?

- Who takes care of reorders?

- These responsibilities don't necessarily have to lie with a single person, but they must be clearly assigned.

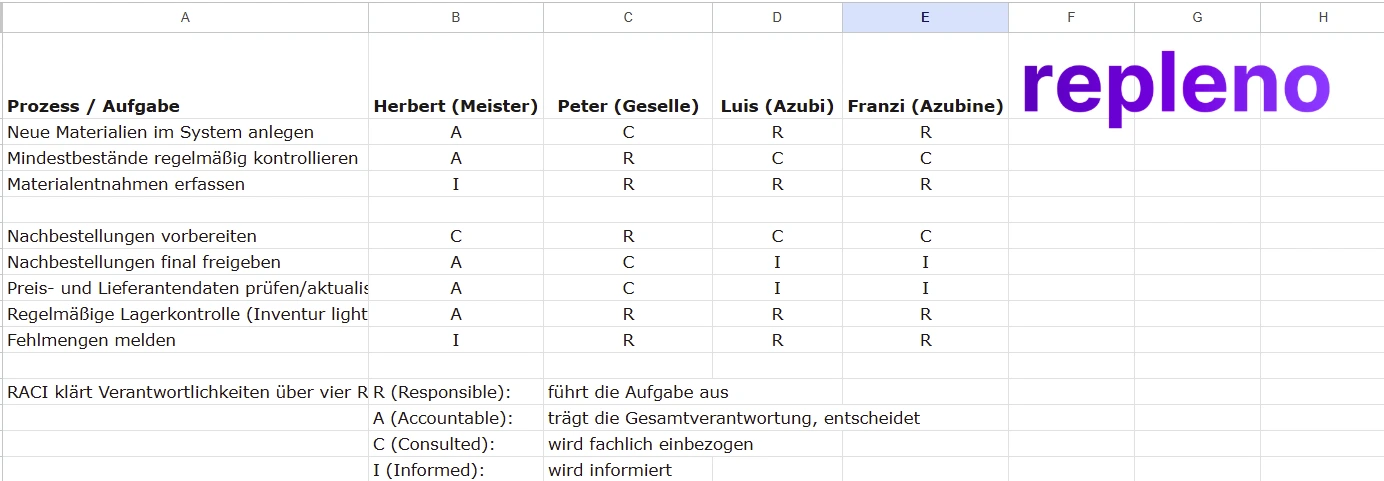

A RACI scheme (Responsible, Accountable, Consulted, Informed) helps create clarity.

Particularly important is the regulation for exceptional situations. What happens when the inventory manager is on vacation? Who steps in when someone gets sick? These substitution rules should be documented so the system continues running even in unforeseen situations. The best inventory management in trades without ERP is robust enough to withstand personnel fluctuations.

Missing Inventories

Many businesses treat digital inventory management as a perfect system that needs no control. Reality looks different: Even the best system can only be as good as the data it contains. When material withdrawals aren't consistently recorded, when deliveries are incorrectly booked, or when material is damaged and must be disposed of, digital inventory deviates from real inventory.

Regular inventories balance these deviations. For trade businesses, annual full inventories are usually sufficient, supplemented by spot checks on important materials. Modern inventory solutions make inventories easy: With the smartphone, shelves are walked through, every article is scanned, and the actually counted quantity is entered. The system automatically compares with target inventory and shows deviations.

These inventories should not be seen as a bothersome duty but as quality control of the entire system. Large deviations show that processes aren't working. Perhaps employees don't consistently record their withdrawals, perhaps there's shrinkage through theft or damage. The inventory makes these problems visible so countermeasures can be taken.

Incorrect Inventory Location Labeling

A digital inventory system is only efficient when physical reality reflects the digital information. When the system says a material is in Shelf 3, but it's actually in Shelf 7, the system becomes a source of frustration instead of efficiency. Employees lose trust and revert to old methods.

The solution begins with clear, logical inventory location labeling. Shelves should be numbered, compartments clearly designated. A system like "R3-F2" for Shelf 3, Compartment 2 is simple and works. This labeling should be both physically attached at the shelf and stored in the digital system. When material is relocated, both the physical position and digital recording must be updated.

It's helpful to assign materials fixed standard locations. Cables always lie in a certain area, tools in another, small materials in a third. This consistency not only facilitates finding but also cleaning and inventory. New employees or temporary workers can orient themselves faster when a clear system is recognizable.

You can read about how to organize inventory in another article: How to Organize Your Inventory in the Trades: Efficient Storage + Digital Tools [2025]

Costs of Modern Inventory Management Without ERP Systems

Monthly License Costs

License costs of modern inventory management solutions are surprisingly low. Simple systems for small businesses start at about ten euros per user per month. More comprehensive solutions with advanced functions like automatic orders, multi-location management, and detailed reports typically lie between thirty and fifty euros monthly. Even in this price range, annual costs remain well below six hundred euros – a fraction of what an ERP system costs.

Many providers scale their prices by number of users or scope of managed articles. A small business with three employees and two hundred articles pays less than a medium business with ten employees and a thousand articles. This scaling is fair and ensures that every business only pays for what they really need. Important is to watch for hidden costs: Are there fees for updates? Does support cost extra? Are there minimum contract terms? Flat fee or seat-based (per user)?

The low costs should not obscure the value of the solution. Even an inexpensive inventory management can bring significant savings when consistently used. The investment of fifty euros per month often pays for itself when a single material shortage on a construction site is prevented. The costs for an emergency order at the wholesaler, driving time, and project delay usually significantly exceed the monthly fee.

Hardware Costs (Scanners, Smartphones)

In addition to software costs, hardware costs may arise. The good news: In many cases, no additional hardware is needed. If employees already have company smartphones, these can be used for inventory management. The smartphone camera is completely sufficient for scanning barcodes. No additional costs arise.

For businesses that don't yet have smartphones in use, an investment makes sense. A solid mid-range smartphone costs about three hundred euros and can be used for many years. For environments with high stress – dust, moisture, falls – there are robust outdoor smartphones from about four hundred euros. This investment pays off quickly because the devices can be used not only for inventory management but also for communication, project documentation, or digital time tracking.

Dedicated barcode scanners are optional. They speed up scanning and are sometimes more practical than smartphones in dusty environments. Simple scanners are available from about one hundred euros, professional industrial scanners cost up to three hundred euros. For most trade businesses, this investment is not strictly necessary. Smartphones are completely sufficient for the start. Scanners can be added later when daily practice shows they would further improve the workflow.

Time Savings as ROI

The return on investment of an inventory management solution can be concretely calculated. Let's take an average trade business with five employees. Before digitization, each employee spent about fifteen minutes daily on stock search, stock checking, and manual documentation. That's about six hours per month per employee, thirty hours monthly for five employees.

With digital inventory management, this effort reduces to about five minutes per employee per day, so about two hours monthly per person or ten hours total. Time savings amount to twenty hours per month. At an average full cost rate of fifty euros per hour, this corresponds to savings of one thousand euros monthly. Against this stand software costs of perhaps forty euros – an ROI of 2400 percent.

Added to this are indirect savings: fewer material losses, fewer emergency orders at inflated prices, fewer project delays, better customer satisfaction. These factors are harder to quantify but contribute significantly to economic success. Businesses that have introduced inventory management regularly report that the investment fully paid for itself within the first three to six months.

If you want to know how high your savings potential is, it's worth trying our simple calculator: Savings Calculator

Future Trends in Digital Inventory Management

AI-Supported Inventory Optimization

Artificial intelligence will revolutionize inventory management in trades. First systems already use machine learning to recognize consumption patterns and optimize order quantities. A painting business that regularly consumes more facade paint in spring gets automatically adjusted minimum stock levels suggested by the system. The AI learns from historical data and adapts to seasonal fluctuations.

AI becomes particularly exciting in predicting material needs for specific projects. Instead of a project manager having to manually estimate which materials are needed, the AI analyzes similar past projects and creates a precise material list. A plumbing business planning a bathroom renovation gets a list from the system based on dozens of previous bathroom renovations – including deviations and special cases that occurred then.

Future systems will also incorporate external data. Weather forecasts could influence order quantities for outdoor work. Economic data could warn of supply shortages and advise preventive orders. The integration of various data sources will make inventory management from a reactive to a proactive, forward-looking discipline.

Automatic Material Quantity Calculation

The future lies in direct linking of projects and inventory management. An electrician plans an installation and enters parameters: room size, number of sockets, light points. The system automatically calculates how much cable, how many boxes, how many switches are needed. It checks availability in stock and suggests reordering missing materials.

This automation not only saves time but also reduces errors. Manual calculations easily overlook small materials or underestimate waste. Intelligent systems consider experience values from previous projects and calculate realistic buffers. They know that cable installation typically has ten percent waste and calculate accordingly more material.

Material quantity calculation will also be integrated with BIM (Building Information Modeling) and digital plans. An architect delivers a digital construction plan, and inventory management automatically extracts the needed materials. This seamless integration between planning and execution will further increase efficiency in trades.

IoT Sensors for Real-Time Data

The Internet of Things will elevate inventory management to a new level. Intelligent shelves with weight sensors automatically recognize when material is withdrawn. No scanning needed anymore – the system registers the withdrawal and updates inventory in real time. Air tags on tools and machines show at any time where which device is located.

Temperature and humidity sensors monitor storage conditions for sensitive materials. Paints, varnishes, or adhesives that lose their properties with incorrect storage are optimally stored. When deviations from ideal conditions occur, the system automatically warns. This prevents quality problems and protects valuable materials.

Particularly interesting for mobile trades are GPS-based systems. Tools and materials in vehicles are tracked in real time. A technician sees on their smartphone not only that a certain part is available but also that it's in colleague Schmidt's vehicle who is working five kilometers away. This transparency enables spontaneous coordination and avoids unnecessary trips.

The question is not if, but when these technologies will be introduced. However, the cost question is still a major obstacle to date.

FAQ on the Best Inventory Management in Trades Without ERP

Does inventory management without ERP actually work reliably for professional requirements?

Yes, modern specialized inventory solutions are often even more efficient for trade businesses than complex ERP systems. They focus on the actually needed functions and forgo unnecessary complexity. While ERP systems try to map all business processes, inventory solutions focus on inventory management, material withdrawals, and reorders. This specialization leads to higher user-friendliness and better performance in exactly the area that matters. Thousands of trade businesses in Germany successfully use such systems and have professionalized their inventory processes with them.

Do I absolutely need barcode scanners or are smartphones enough?

Smartphones are completely sufficient. The camera of modern smartphones is more than powerful enough to quickly and reliably capture barcodes. Dedicated scanners are more comfortable and more practical in very dusty or moist environments, but not a must. Many businesses start with smartphones and decide after a few months of practical experience whether additional scanners would further improve the workflow. The great advantage of smartphones is that they're available anyway and can be used for many other purposes – from communication to photo documentation on construction sites.

Is cloud inventory management really secure and GDPR-compliant?

Yes, serious providers use state-of-the-art encryption technologies and meet strict German data protection standards. Many solutions store data exclusively in German data centers, ensuring highest GDPR compliance. Data in professional cloud environments is often safer than on local servers in workshops that aren't protected against fire, theft, or water damage. Cloud providers invest millions in security infrastructure, multi-factor authentication, and regular backups. Businesses should pay attention to certifications when selecting and clarify where data is stored.

How long does implementation of inventory management realistically take?

Technical implementation takes between a few hours and one to two days. In this time, the most important materials are recorded, the system configured, and employees trained. Complete organizational integration takes about two to three months, during which the team develops routine and all processes are optimized. The key is a step-by-step approach: Start with the most important materials, gather experience, then expand. Businesses that try to digitize everything at once often overwhelm themselves. A focused start with the twenty percent of materials that affect eighty percent of projects is the proven way.

What does a good inventory management app actually cost per month?

Professional inventory management for trade businesses typically costs between ten and 150 euros monthly, depending on number of users and feature scope. Simple solutions for small businesses start at about ten euros, more comprehensive systems with automatic orders, multi-location management, and detailed reports lie at thirty to 150 euros. Added to this are possibly one-time costs for smartphones or scanners if these aren't available yet. The total investment is significantly lower than with ERP systems and typically pays for itself through time savings and reduced material losses within three to six months.

Is digital inventory management worth it even for very small businesses with only two to three employees?

Absolutely – often the benefit is even greatest for small businesses. Small teams usually don't have a dedicated person for inventory management, so everyone must do everything. Digital solutions create transparency and relieve all involved. Especially in small businesses, where every error directly impacts, reliable inventory management is existential. Costs are minimal compared to savings through avoided wrong orders or project delays. Moreover, systems scale: When the business grows, inventory management simply grows with it without basic processes having to be changed.

Conclusion

The best inventory management in trades is not a distant future vision but available reality today. Specialized solutions have proven that efficient inventory management doesn't require complex ERP systems but can be achieved with lean, mobile tools that fit the way trades work.

The advantages are overwhelming:

- drastic reduction of material losses

- time savings through automated processes

- better project planning through transparent inventory and freedom from constant ordering stress.

Trade businesses that take the step toward digital inventory management regularly report quick payback and noticeable relief in day-to-day operations.

Getting started is easier than many think. With minimal costs, quick implementation, and intuitive operation, barriers are low. Technology is mature, providers understand the requirements of trades, and success stories speak for themselves. For trade businesses that want to work more efficiently, operate more profitably, and relieve their employees, there's no way around digital inventory management.

The best time to start was yesterday. The second best time is today. With digital solutions that free tradespeople from paper-based processes and automate reorders, inventory management becomes from a problem area to a competitive advantage. Trade businesses that digitize now secure a clear lead over competitors still struggling with manual processes.

If you want to know how to automate your material management and which exact tools come into question, feel free to check here: Digital Procurement in Trades: 12 Strategies for Automated Material Management