Min-Max Inventory Management for Trades & Crafts: Practical Guide 2025

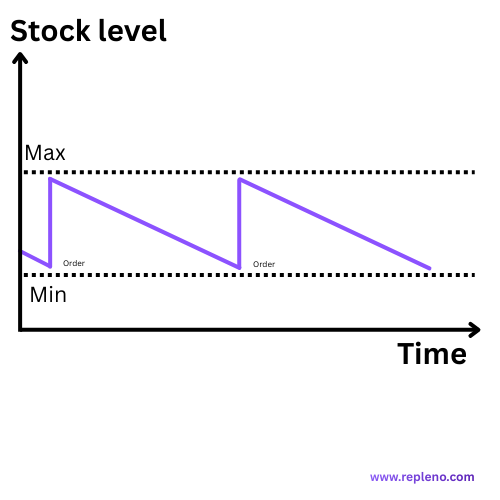

TL;DR: Min-max inventory management sets a minimum and maximum stock level for each item. When the minimum stock is reached, the system automatically triggers an order. This prevents material shortages and reduces unnecessary storage costs. Especially valuable for craft businesses with 50+ different items.

Introduction: Why Min-Max Inventory Management in Trades?

You know the feeling? Monday morning on the construction site – and exactly the M8 screws you need for the installation are missing. Or the opposite: Your warehouse is overflowing with cable glands you bought in bulk two years ago.

This is exactly where min-max inventory management comes in: It creates the balance between "always enough in stock" and "not letting money sit on the shelf."

The Problem: Traditional ordering methods in trades are often based on gut feeling or the principle "We order when it's empty." This leads to:

- Missing parts on the construction site due to material shortages

- Unnecessarily high storage costs due to overstock

- Time loss due to emergency orders and special trips to the hardware store or wholesaler

The Solution: The min-max principle automates ordering decisions based on clear metrics instead of intuition.

Find out how much missing materials cost you per year in our article on Material and Missing Parts.

What Does Min-Max Inventory Management Mean Specifically?

Min-max inventory management is a rule-based inventory management system in which two threshold values are defined for each warehouse item:

- Minimum Stock (Min): The critical quantity below which stock should not fall

- Maximum Stock (Max): The optimal storage quantity that should not be exceeded

Basic Principle: As soon as the current stock reaches or falls below the minimum stock, an order is automatically triggered that brings the stock back to the Max level.

Min-Max Procedure in the Warehouse: The System Behind It

The min-max procedure in the warehouse belongs to the family of reorder point methods and is also referred to as min-max system in logistics. In materials management, this min-max model for inventory levels has proven itself for decades – especially in industries with predictable consumption.

In contrast to just-in-time approaches, min-max inventory management relies on defined safety buffers. This makes it ideal for craft businesses with consumables that don't want to rely on expensive emergency orders and special trips.

The Gabler Business Dictionary defines inventory management as "all decisions and actions that influence inventory levels" – whereby inventories are formed to compensate for temporal discontinuities and to bridge disruptions. The min-max procedure is one of the most practical implementations of this definition.

Practical Example: Electrical Installation Business

Item: NYM-J 3x1.5 mm² (100m rolls)

- Minimum Stock: 2 rolls

- Maximum Stock: 5 rolls

- Current Stock: 2 rolls → Order is triggered

- Order Quantity: 3 rolls (to get back to 5)

How Does the Min-Max Procedure Work in the Warehouse? The Three Core Elements

1. Minimum Stock (Min) – The Safety Buffer

The minimum stock consists of:

Min = Safety Stock + Consumption During Lead Time

Example Calculation (HVAC Business):

- Item: Fittings 1/2"

- Average Consumption: 20 pieces/week

- Supplier Lead Time: 1 week

- Desired Safety Buffer: 1 week extra

Calculation:

- Consumption during lead time: 20 pieces

- Safety stock: 20 pieces

- Minimum Stock = 40 pieces

2. Maximum Stock (Max) – The Economic Upper Limit

The maximum stock considers:

- Storage capacity

- Capital commitment

- Shelf life/perishability

- Volume discounts

Max = Min + optimal order quantity

The optimal order quantity depends on:

- Order costs (shipping, effort)

- Storage costs

- Volume discounts from the supplier

3. Reorder Point and Automatic Triggering

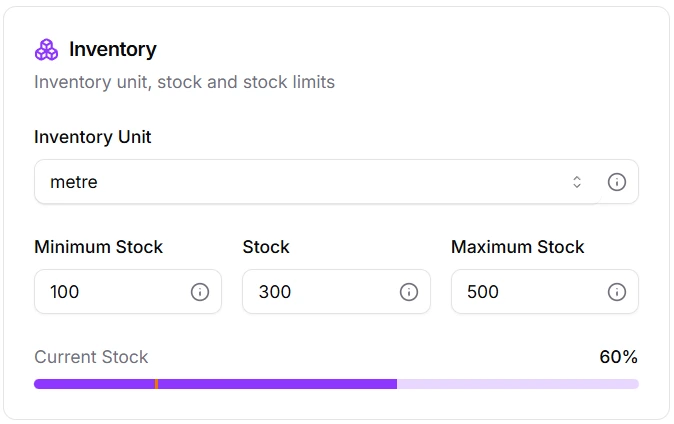

Modern Systems (such as repleno) continuously monitor stock and automatically trigger orders as soon as:

- The minimum stock is reached or undershot

Visualization of the min-max configuration in repleno:

The 7 Most Important Advantages of Min-Max Inventory Management

1. Cost Control Through Reduced Overstock

2. No More Production Stops

3. Less Time Spent on Orders

Automation Saves Time:

- Manual checking is eliminated

- Order suggestions are pre-calculated

- Bulk orders are possible

4. Better Supplier Conditions

Plannable order quantities enable negotiations on:

- Volume discounts

- Fixed delivery times

- Annual contracts

5. Optimized Storage Space

Less overstock = more space for:

- Tools

- Project materials

- Returned goods

6. Transparency for the Entire Team

Every employee sees:

- Which items are critical

- When reordering happens

- Who is responsible

7. Better Liquidity

Lower capital commitment means:

- More room for investments

- Less need for credit

- Higher creditworthiness

Areas of Application: Where Min-Max Inventory Management is Particularly Effective

Electrical Installation

Typical Min-Max Items:

- Cables and wires (NYM, NYY)

- Installation materials (boxes, screws)

- Fuses and small parts

- Connection materials

HVAC (Heating, Ventilation, Air Conditioning)

Typical Min-Max Items:

- Fittings and connections

- Sealing materials

- Pipe clamps

- Standard fittings

Carpentry/Joinery

Typical Min-Max Items:

- Screws and hardware

- Glue and chemicals

- Abrasives

- Standard profiles

Auto Repair Shop

Typical Min-Max Items:

- Oil filters (common types)

- Brake fluid

- Gaskets

- Standard screws

💡 Rule: The min-max system in logistics is suitable for consumables of all kinds.

- C-Items (frequently needed, low value)

- B-Items (medium value, regular demand)

- For A-items (high value, rare), other methods are more appropriate.

Calculating Min-Max Values Correctly: Step by Step

Step 1: Collect Consumption Data

At least 3 months, better 12 months of consumption history to analyze:

- Average consumption/week

- Seasonal fluctuations

- Trends (rising/falling)

Step 2: Determine Lead Times

Document Real Lead Time:

- From order to goods receipt

- Including buffer time for delays

- Differences between standard suppliers and backup suppliers

Step 3: Set Safety Stock

Rules of Thumb:

- Standard items: 1 week safety buffer

- Critical items: 2 weeks buffer

- Hard to procure: 3+ weeks buffer

Step 4: Optimize Order Quantity

Consider:

- Minimum order quantities from the supplier

- Tiered pricing

- Storage capacity

- Perishability/shelf life

Complete Calculation Example for Min-Max Materials Management

Item: Cable Glands M20 (Electrical Business)

Data Basis:

- Average Consumption: 50 pieces/week

- Lead Time: 1 week

- Desired Safety Buffer: 1 week

- Supplier offers tiered pricing from 500 pieces

Minimum Stock Calculation: Min = (50 pieces/week × 1 week) + (50 pieces/week × 1 week)

Min = 100 pieces

Maximum Stock Calculation:

- Optimal order quantity due to tiered pricing: 500 pieces

- Max = 100 + 500

Max = 600 pieces

Result:

- At ≤ 100 pieces in stock → Trigger order of 500 pieces

- Target stock after delivery: 600 pieces

Min-Max Inventory Management with Modern Software

Automation Through Digital Inventory Management

Modern inventory management systems such as repleno take over:

✅ Automatic Stock Monitoring in Real Time

✅ Order Suggestions or Automatic Reordering as soon as Min is reached

✅ Supplier Integration for Direct Ordering

✅ Consumption Analysis for Optimizing Min-Max Values

✅ Mobile Recording via Barcode/Scanner via App

Integration into Existing Systems

Typical Interfaces:

- ERP Systems (SAP, Microsoft Dynamics)

- Warehouse Management

- Supplier Portals

- Accounting Software

Min-Max Inventory Management is not only automated by digital tools but also continuously optimized: Machine learning recognizes consumption patterns and suggests adjustments to min-max values.

The 5 Most Common Mistakes in Min-Max Inventory Management

❌ Mistake 1: Set Min-Max Values Once and Forget

Problem: Consumption patterns change, suppliers change lead times

Solution: Quarterly review + adjustment for major changes

❌ Mistake 2: Too High Safety Stocks Out of Caution

Problem: Capital commitment increases unnecessarily

Solution: Start with realistic buffers, then refine

❌ Mistake 3: Manage All Items with Min-Max

Problem: High-priced special parts don't fit the min-max scheme

Solution: ABC Analysis – only B- and C-items and general consumables with min-max

❌ Mistake 4: Estimate Consumption Data from Gut Feeling

Problem: Wrong basis = wrong values

Solution: Use at least 3 months of real consumption data

❌ Mistake 5: No Consideration of Seasonality

Problem: Too much heating material in summer, too few climate components in winter

Solution: Create seasonal min-max profiles

Best Practices for Successful Min-Max Inventory Management

1. Start with a Pilot Group

Recommendation: Select 20-30 items with high consumption

→ Gather experience → then expand

The REFA Federal Association recommends for efficient inventory management the clear definition of metrics such as safety, reorder and maximum stock. These values form the basis for successful min-max systems – especially in manufacturing businesses and trades.

2. Document Supplier Performance

Track:

- Actual lead times

- Delivery reliability

- Quality problems

3. Use Dashboards for Overview

Important KPIs in Min-Max Procedure Warehouse:

- Number of items below minimum stock

- Average stock coverage

- Capital commitment in warehouse

- Order frequency

4. Involve the Team

Communication:

- Assembly meetings with warehouse status

- Feedback channel for material problems

- Training for new employees

5. Automate Routine Tasks

What Software Should Take Over:

- Daily stock checking

- Generation of order suggestions or automatic order sending ← better

- Notifications for critical stock levels

- Reporting

Future Trends: Where is Min-Max Inventory Management Heading?

Predictive Analytics

Next Generation: AI recognizes patterns and automatically adjusts min-max values:

- Seasonal fluctuations

- Project-based peaks

- Supplier failures

IoT Integration in Min-Max System Logistics

Smart Bins: Sensors capture fill level in real time:

- Scales for bulk goods

- Optical sensors

Supplier Integration

Direct Procurement: Orders go out automatically:

- EDI connection to wholesalers

- API interfaces

- Automatic order confirmation

Terminology: Min-Max in Various Contexts

Depending on the field and industry, the method is referred to differently:

| Term | Focus | Typical Context |

|---|---|---|

| Min-Max Procedure Warehouse | Operational Warehousing | Warehouse Manager, Logistics Personnel |

| Min-Max System Logistics | Supply Chain Integration | Logistics Planning, SCM |

| Min-Max Inventory Management | Controlling/Management Perspective | Management, Controller |

| Min-Max Materials Management | Production and Procurement Focus | Purchasing, Production Planning |

| Min-Max Model Inventory Level | Theoretical/Academic View | Business Literature, Universities |

All terms describe the same basic principle: Automatic order triggering when minimum stock is reached to keep inventory levels between defined limits.

Conclusion: Min-Max as the Foundation of Efficient Warehousing

Min-max inventory management is not rocket science – but it is effective, calculable and scalable. For craft businesses, it offers the perfect balance between automation and control.

The Three Most Important Takeaways:

- Min-max reduces capital commitment by an average of 30-40% while simultaneously increasing material availability

- Automation is the key – manual min-max management only works up to about 50 items

- Continuous optimization beats perfect initial setup – start pragmatically, improve iteratively

The min-max procedure in the warehouse has established itself as one of the most reliable systems in materials management. With modern tools, the min-max model for inventory levels not only becomes easier to apply but also smarter through AI-supported optimization.

Ready for Automatic Orders? repleno takes over min-max monitoring for you. Your warehouse orders by itself. → [Get Started Now]