TL;DR: The Reorder Point Method automatically orders when a calculated threshold is reached – ideal for valuable items with fluctuating demand. Min-Max orders when stock falls below the minimum level – simple for C-items with stable consumption. The best solution? A hybrid combination of both methods for different item groups.

Choosing the right inventory control method is a decisive factor for the economic success of a company. Those responsible often face the question: Reorder Point Method vs. Min-Max – which system is better? Both methods aim to avoid material shortages while simultaneously reducing inventory costs. However, they differ significantly in their functionality, flexibility, and area of application.

This article explains Reorder Point Method vs. Min-Max comprehensively, practically, and understandably – ideal for purchasing, logistics, controlling, and students.

Introduction to Inventory Control

Expert Knowledge: According to VDI Guideline 3601 "Warehousing and Material Flow" (2025), optimized inventory control methods can reduce inventory costs by 15-25% while increasing delivery capability to over 98%.

Inventory control means having the right item in the right quantity available at the right time. Poor control leads to either stock shortages or excessive inventory levels, which bind capital and cause costs.

Classic methods include:

- Reorder cycle method

- Reorder Point Method

- Min-Max Method

The focus of this article is the comparison Reorder Point Method vs. Min-Max, as both are particularly widespread.

Brief Overview: What Happens When Ordering?

Both methods essentially answer two questions: When do I order? and How much do I order?

- Reorder Point Method (s, Q): If the stock falls to/below the reorder point s, a fixed quantity Q is ordered.

- Min-Max Method (s, S): If the stock falls to/below Min = s, enough is ordered so that the stock reaches Max = S again (Order quantity = S − available stock).

Practical Note: Depending on the ERP/WMS, it is not just the physical stock that counts, but the available stock (e.g., minus reservations, plus open incoming goods).

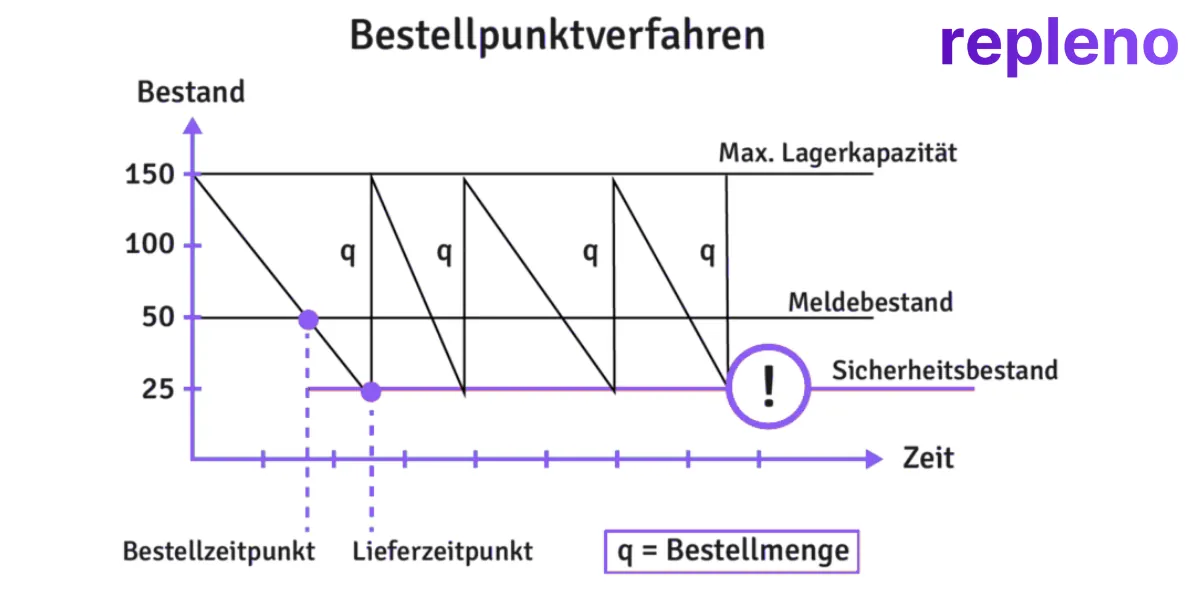

Basics of the Reorder Point Method

Definition and Functionality

With the Reorder Point Method, an order is always triggered when the inventory level reaches or falls below a defined reorder point. This reorder point takes into account:

- Average consumption

- Lead time

- Safety stock

The method is consumption-oriented and reacts dynamically to inventory movements.

Note: The reorder point answers the When. The order quantity (e.g., packaging unit/MOQ or a calculated lot size) answers the How much.

Calculation of the Reorder Point

The classic formula is:

Reorder Point = Daily Consumption × Lead Time + Safety Stock

Example:

- Daily consumption: 20 units

- Lead time: 5 days

- Safety stock: 50 units

➡ Reorder Point = (20 × 5) + 50 = 150 units

As soon as the inventory reaches 150, an order is placed.

Advantages of the Reorder Point Method

- High supply security

- Flexible reaction to consumption fluctuations

- Lower inventory levels possible

- Good for continuously demanded items

This method is very popular, especially for A-items or critical components.

Disadvantages of the Reorder Point Method

- High monitoring effort

- Exact consumption data required

- Complex for many items without IT support

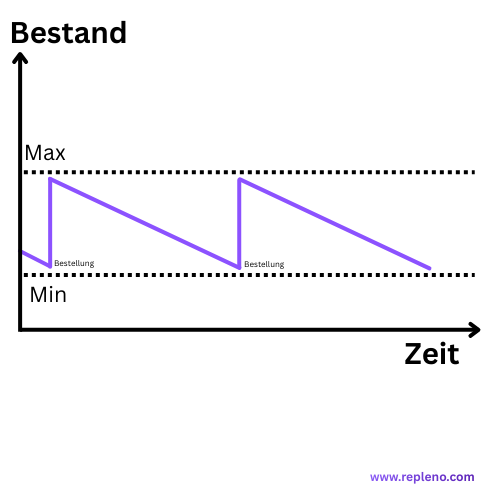

Basics of the Min-Max Method

Definition and Functionality

With the Min-Max Method, two fixed inventory limits are defined:

- Minimum Stock (Min)

- Maximum Stock (Max)

If the inventory level falls below the minimum stock, it is replenished up to the maximum stock.

Note: Min-Max is a "fill-up-to" principle. The order quantity results from Max − available stock (not as a fixed quantity).

Calculation of Minimum and Maximum Stock

- Minimum Stock = Consumption during lead time + Safety Stock

- Maximum Stock = Minimum Stock + Optimal Order Quantity

Pragmatic: "Optimal Order Quantity" is often simply the sensible lot/pack size in practice (packaging unit, MOQ, pallet layer). If you want to be more precise, you can refine it later with EOQ/Andler.

Example:

- Minimum Stock: 100 units

- Optimal Order Quantity: 300 units

➡ Maximum Stock = 400 units

Advantages of the Min-Max Method

- Simple handling

- Less monitoring necessary

- Well-plannable order quantities

- Ideal for C-items

Disadvantages of the Min-Max Method

- Higher inventory levels

- Less flexible with demand fluctuations

- Risk of overstocking

If you are thinking about integrating a Min-Max method, check out our advanced practical guide: Min-Max Inventory Management for Trades

Reorder Point Method vs. Min-Max – Direct Comparison

| Criterion | Reorder Point Method | Min-Max Method |

|---|---|---|

| Trigger | When reaching the reorder point | When falling below Min |

| Flexibility | High | Medium |

| Inventory Level | Lower | Higher |

| Administrative Effort | High | Low |

| IT Dependency | High | Low |

| Suitability | A- & B-Items | B- & C-Items |

Setting Parameters (Without Math Overkill)

If you want to start with a clean setup, these 4 building blocks are often enough:

- Consumption: Ø Consumption per day/week (best from the last 8–12 weeks, seasonally separated if applicable).

- Lead Time: Realistic lead time (Average + Buffer) instead of "catalogue value".

- Safety Stock: Conscious service level (e.g., 95%) + consider fluctuation.

- Lot Size: Packaging unit/MOQ as a start; later refine for cost optimization if necessary.

Flexibility and Reaction Speed

In the direct comparison Reorder Point Method vs. Min-Max, it shows:

The Reorder Point Method reacts faster to changes in consumption, while Min-Max is rather stable and plannable.

Inventory Costs and Tied-up Capital

- Reorder Point Method: Lower tied-up capital

- Min-Max: Higher stocks, higher inventory costs

Planning and Administrative Effort

Without an ERP system, the Reorder Point Method is hardly practicable. Min-Max, on the other hand, is also suitable for smaller companies and is used in many inventory apps.

Calculation Examples from Practice

Mini-Example: Same Item, Both Methods

Approximation:

- Ø Consumption: 20 units/day

- Lead time: 5 days

- Safety stock: 50 units

- Lot size/Pack size: 300 units

Then:

- Reorder Point s = 20 × 5 + 50 = 150 units

- Reorder Point Method (s, Q): If Stock ≤ 150 → order Q = 300

- Min-Max (s, S): Min = 150, Max = 150 + 300 = 450 → if Stock ≤ 150 → order (450 − available stock)

Use Case 1: Mechanical Engineering (A-Item)

➡ Reorder Point Method due to high value and critical supply

Use Case 2: Trading Company (C-Item)

➡ Min-Max due to simple planning and low importance of individual items

Typical Areas of Application for Both Methods

Reorder Point Method:

- Automotive industry

- Mechanical engineering

- Spare parts management

Min-Max Method:

- Retail

- Office supplies

- Consumables

Common Mistakes in Practice

Mistake 1: Safety Stock Set Too Low

Many companies set the safety stock "by gut feeling". Better: first choose a service level (e.g., 95%) and derive the safety stock from the consumption fluctuation.

Simple Start (if lead time is relatively stable):

Safety Stock = z × σ(Consumption) × √(Lead Time)

Typical z-values: 90% ≈ 1.28, 95% ≈ 1.65, 99% ≈ 2.33. If lead times fluctuate strongly, this variance should also be taken into account (or you calibrate based on real stockouts).

Mistake 2: Lead Times Calculated Incorrectly

Often only the lead times stated by the supplier are used. In reality, you should include the average of the last 12 deliveries plus a buffer time of 10-20%.

Mistake 3: Method Not Adapted to Demand

An A-item with fluctuating demand needs a different method than a C-item with constant consumption. Best Practice: Perform ABC analysis and choose method per item group.

Mistake 4: Lack of Regular Review

According to VDI Guideline 3601, parameters should be reviewed at least quarterly. For seasonal fluctuations or product changes, even monthly.

Digitalization & Modern Inventory Control

Modern ERP and WMS systems today combine both approaches. Hybrid models allow:

- Automatic determination of reorder points based on consumption history

- Dynamic Min-Max limits that adapt to seasonality

- AI-supported forecasts for more precise demand planning

- Real-time stock monitoring with automatic order triggering

Software Approaches in Comparison

Enterprise Solutions (SAP, Oracle):

- Fully integrated reorder point logic

- Complex parameterization

- Ideal for large companies with >10,000 items

Mid-sized Solutions (Odoo, lexoffice):

- Combination of Reorder Point and Min-Max

- Simpler configuration

- Good for 500-5,000 items

Specialized Inventory Apps (repleno):

- Focus on Min-Max with automatic order triggering

- Optimized for trades and small businesses

- Fast implementation without IT department

Neutral, further resources for reference:

- VDI Guideline 3601 – Warehouse Management Systems (German)

- Gabler Business Dictionary: Reorder Point Method (German)

- Gabler Business Dictionary: Safety Stock (German)

Checklist: Which Method Suits Your Company?

Choose Reorder Point Method if:

- ✅ You manage A-items or critical components

- ✅ Consumption fluctuates strongly (>30% standard deviation)

- ✅ ERP system or inventory management software available

- ✅ Tied-up capital should be minimized

- ✅ Delivery capability >98% is required

Choose Min-Max Method if:

- ✅ You have B/C-items with stable consumption

- ✅ Simple handling is more important than optimal stocks

- ✅ No complex IT infrastructure available

- ✅ Order quantities are standardized (e.g., pack sizes)

- ✅ Manual monitoring is sufficient

Choose Hybrid Model if:

- ✅ You have 500+ items in different ABC classes

- ✅ Flexibility depending on item type is desired

- ✅ Modern inventory software is available

Conclusion: Which Method is Better?

The decision Reorder Point Method vs. Min-Max depends heavily on the area of application.

- High value, fluctuating consumption: Reorder Point Method

- Low value, stable consumption: Min-Max

Companies benefit most when they combine both methods specifically and review them regularly.

How to embed reorder point and min-max into a structured stockroom system is explained in our complete guide: How to organize your warehouse in the trades: Efficient storage & digital tools.